AQUATRON WASTE WATER RECOVERY TECHNOLOGY

FPSTAR Process Benefits:

- Reduce COD and BOD by 95% +

- Agglomerate particles as small as 0.01 μm in water to 10 μm to 1.5 mm and filtered through conventional aids.

- Extremely fast reaction time, processes water on line and clean water available for recycle immediately.

- Arsenic, Nitrates, Heavy Metals and Fluoride reduction.

- Softening Solids as fast sedimentation Aid.

- Very small space requirements.

- Very effective in the removal of high and low turbidity.

- Extremely effective in removal of Colour, TOC, NOM and DBP precursors.

- Works over a wide pH range.

- Low cost of operation compared to conventional methods of water treatment and recovery.

- Makes heavier particles that settles faster.

- Produces higher sludge concentrations resulting in Lower sludge disposal costs.

About 70% of the earth’s surface is covered with water. Ninety-seven percent of the water on the earth is salt water. Salt water is saturated with salt and other minerals, and humans cannot drink this water. Although the salt can be removed, it is a difficult and expensive process.

Two percent of the water on earth is glacier ice at the North and South Poles. This ice is fresh water and could be melted; however, it is too far away from where people live to be usable. Less than 1% of all the water on earth is fresh water that we can actually use. We use this small amount of water for drinking, transportation, heating and cooling, industry, and many other purposes.

Water Issues Today …

In India, the industrial segment is the second highest consumer of water. It is estimated that the current industrial water use in India is about 13 per cent of the total freshwater withdrawal in the country and the water demand for industrial uses and energy production will grow at a rate of 4.2 per cent per year, rising from 106 billion cubic metres in 2013 to 228 billion cubic metres by 2025. All these estimates reveal that the industrial water demand is not negligible in India and that it is bound to grow in the coming years. Industries not just consume water but also pollute it. According to the World Development Report (WDR) of 2003, in developing countries, 70 per cent of industrial wastes are dumped without treatment, thereby polluting the usable water supply. Note that industrial water demand is not the demand for water as in other sectors, as a large part of the water withdrawn for industrial use is discharged as polluted water by the industries. According to CSE (2004), on an average, each litre of wastewater discharged further pollutes about 5–8 litres of water which raises the share of industrial water use to somewhere between 35–50 per cent of the total water used in the country, and not the 7–8 per cent that is considered as the industrial water use. Polluted water is very rarely used by industries.

The waste water treatment system used by most of the industries are essentially installed to meet the wastewater discharge norms, which are concentration based, that is, they measure the concentration of pollution in a given quantity of water. The result is that an industry can meet the required standard merely by diluting the waste water with clean water. Since the cost of water is low, it makes more economic sense for an industry to dilute the effluent than to treat it to meet the standards.

Water once used is generally thrown without any further use, even if it can be reused. Segregation of wastewater from various processes into clean water (that can be reused), and contaminated water, is not commonly done. The result is that even the uncontaminated water gets contaminated after mixing and is discharged as effluent.

Why scarcity occurs …

India today consumes 693 billion cubic metre (1 Cubic Metre = 1000 litres) of water annually, this is going to increase to 942 billion cubic metre by 2025 and 1,422 billion cubic metre by 2050. Have we ever thought how we are going to meet this demand?

On the other side, India discharges 48,797 million cubic metres of waste water annually, enough and more for the needs of our entire population. Shouldn’t we have a technology to recover and use this water for sustainable existence?

Process:

FPSTAR stands for Fine Particle Shortwave Thrombotic Agglomeration Reactor. It is a disruptive innovation technology in the water treatment sector. It is inspired by nature, a universal solution for waste, yet customisable to your needs. The process mimics blood clotting in the human body. The unwanted particles are engineered to collide and agglomerate in the reactor and then removed by multi-stage filtration defined by end-use requirement.

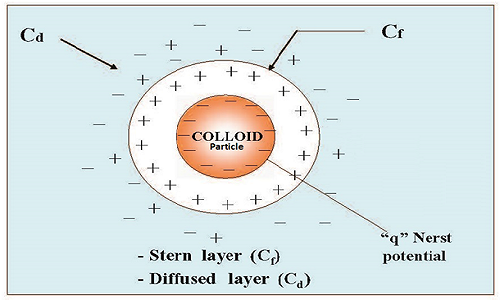

Particles finer than 0.1 μm in water, remain continuously in motion due to electrostatic charge (often negative) which causes them to repel each other. Once their electrostatic charge is striped (neutralised) by the use of a special technique that forms metcomplex ionization, shortwave bombardment and simultaneously causing flow turbulence, the finer particles start to collide and agglomerate (combine together) under the influence of Vander Waals’ forces. These larger and heavier particles are called Thrombus (clots) and the process is called Fine Particle Thrombousthai Reaction and is done in a Fine Particle Thrombousthai Reactor or FPTR.

Applications:

- Pharmaceutical Effluent

- Textile Effluent

- Tannery Effluent

- Breweries

- F&B Manufacturing Industries

- Power Generation Industries

- Oil & Gas

- Sugar Industry

- Pulp & Paper Industries

- Chemical Manufacturing Industries

- And many many more effluent/ waste water streams.

Download Brochure.

For more information on this technology, kindly write to us at info@esclare.org.