EN-STAR (Energy & Nutrients from Solid Trash Automated Recovery) System is an integrated wasted hydrocarbon recovery system suited for solid wastes including Municipal Solid Waste (MSW), Agricultural Waste, Sewage Waste, Water Hyacinth, Food & Kitchen Waste, and any other source of Organic Waste.

In the area of municipal solid waste, it is ideally suited for automated segregation and processing of un-segregated waste to meet the needs of developing countries. The un-segregated waste is treated with water at high temperature and pressure resulting in leachate formation, thereby segregating the hydrocarbons from inorganics for further processing. The inorganic waste is passed through a density separator to segregate Plastics, Metals and Glasses. Residual water may be recovered from the leachate after processing using FP-STAR, a patented technology and recycled back in the process, if required.

In the area of non-municipal waste, solid hydrocarbons like agriculture, water hyacinth, etc. are pulverized, diluted and directly fed for processing.

The wasted hydrocarbon (leachate from municipal waste or pulverized solids) is fed into reactors for bio-methanization and gas refining processes, based on patented technologies. This ensures that the natural gas produced is Grid Grade (IS 16087:2013), high in methane content (95 to 97%), free from Hydrogen Sulphide (H2S) & Carbon Monoxide (CO) and odorless. The entire process is safe and causes very minimum or no air pollution. No incineration or burning is used in the process making it Pollute-Zero (PZ) technology.

Unsegregated Waste Management

Manual segregation is an inefficient and ineffective process, since the level and quality of segregation can never be ensured to the level required by the subsequent process of anaerobic decomposition of organic part. To solve this problem, MSW is fed into a Leachate Extractor, where it is washed with water at high temperature and high pressure. The extreme condition ensures that most of the organic matter is converted to Leachate (organic matter slurry) and is collected in an underground Leachate holding tank. The inorganic matter remaining in the Leachate Extractor is sanitized and then passed through a Trommel Screen where the lighter plastics and the heavier solid organic matter like wood, bottles and metals are separated.

The leachate is passed into a patented high quality microbe incubated bio-reactor where the organic matter is broken down, under anaerobic conditions, in a series of steps to produce methane and carbon dioxide, which can be refined into Organic Natural Gas and used for automobiles, cooking, electricity generation or other thermal applications. The generated gases from the process are stored in tanks to ensure easy management and to prevent air pollution. The added advantage of this solution is that the Hydraulic Retention Time ( HRT ) is as low as 15 to 21 days.

Organic Sludge Management (FP-STAR)

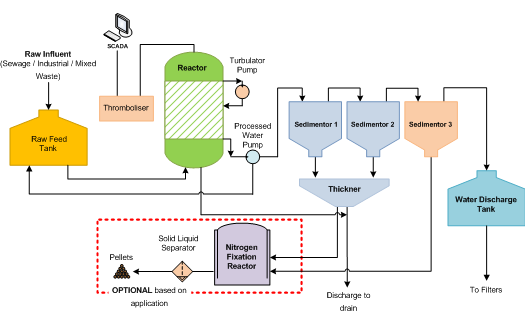

The sludge from post bio-methanization process is fed into FP-STAR, which is a patented technology for Wastewater Recovery and Management. Here, sludge is bombarded with shortwave of a certain frequency, resulting in removal of electrostatic charge of the dissolved and suspended particles. At this stage, the particles start to collide and agglomerate under the influence of Van der Waals forces, thus separating water from clot/sludge. The recovered water can be used back in process and the sludge can be easily filtered out. The entire process is fully automated and does not use any chemical to segregate sludge and water. On the basis of design requirement this stage may be used before Bio-Methanization for optimizing the cost, without impacting the final output.

The sludge from post bio-methanization process is fed into FP-STAR, which is a patented technology for Wastewater Recovery and Management. Here, sludge is bombarded with shortwave of a certain frequency, resulting in removal of electrostatic charge of the dissolved and suspended particles. At this stage, the particles start to collide and agglomerate under the influence of Van der Waals forces, thus separating water from clot/sludge. The recovered water can be used back in process and the sludge can be easily filtered out. The entire process is fully automated and does not use any chemical to segregate sludge and water. On the basis of design requirement this stage may be used before Bio-Methanization for optimizing the cost, without impacting the final output.